| · Risk analysis of the whole plant equipment ·All risk assessment methods ·Performance level PLr required by safety control system ·Safety control system performance level PL ·Declaration of conformity report |

| Basic construction |

Step 1: Machine Definition: ·Is to determine the scope of the system to be analyzed, such as the stages of the life cycle of the machine, the parts and/or functions of the machine. Step 2: Hazard Identification: ·The goal of hazard identification is to form a list of hazards, hazardous states and/or hazardous events, which can describe when and how the hazardous states may cause injuries. · Hazard identification is the most important step in any risk assessment. Only after the hazards are identified can actions be taken to reduce the risks associated with them. Unrecognized hazards may lead to injuries. Step 3: Risk estimation Step 4: Risk assessment Step 5: Risk reduction |

| Risk Assessment Risk Reduction Description |

·Risk reduction or reduction is to reduce the risk to an acceptable level by taking protective measures.

·Risk reduction is the ISO12100:2010 standard, which integrates ISO 12100-1: 2003, ISO 12100-2: 2003, ISO14121, ISO15706, ISO13849 and ISO16855. This standard mainly provides designers with what they need when designing and manufacturing safety machinery.

| Use function of intelligent software risk assessment module/linkage module |

Evaluation of some equipment in the factory | Industry evaluation | Job evaluation | Hidden danger assessment |

|

|

|  |

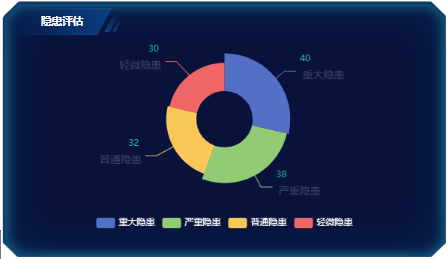

· How many high-risk devices are not evaluated? · How many devices are not evaluated for low risk? · How many units of risk have not been assessed 3. · How many devices have not been evaluated? | · Normal behavior · Frequent violations · To be observed | · Safety assessment of PHA process · JSA operation safety assessment | · Major hidden danger assessment · Serious hidden danger · Common hidden danger · Minor hidden danger |

Use the evaluation software function to standardize the evaluation management of factory equipment, sort out the risk level of all equipment in the factory, and evaluate the loop level of PL safety control system at the same time. If you need to try the software, please contact customer service staff.

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright ? Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing